Description

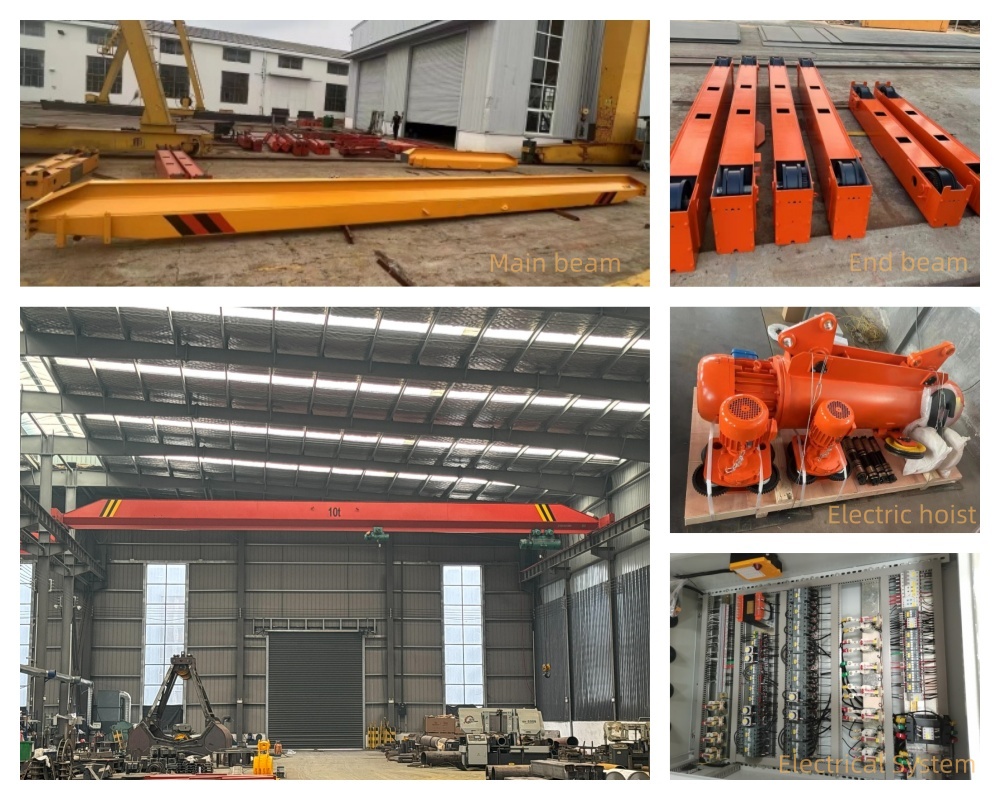

Single girder overhead crane is composed of main beam, end beam,wire rope electric hoist, crane travel system and electrical control system. It is a versatile lifting solution designed for light and medium-load hoisting operations. It features a simple structure, ease of installation, and compact design, making it ideal for indoor material handling in various industries. With a single girder overhead crane, businesses can achieve efficient and safe lifting, especially in factories, warehouses, workshops, and material yards.

1.Compact & Simple Design: Perfect for indoor use with minimal setup required.

2.Energy-Efficient: High efficiency and low energy consumption during operations.

3.Flexible Operation: Easy to control and use with few commands.

4.Safety: Equipped with multiple safety features to ensure smooth operation.

Product Parameters:

|

Load capacity (t) |

1t to 20t |

|

Lifting height (m) |

6~30m |

|

Span(m) |

7.5~31.5m |

|

Lifting speed (m/min) |

8/0.8,7/0.7,3.5/0.35 |

|

Cross moving speed (m/min) |

20/30 |

|

Long moving speed (m/min) |

20/30 |

|

Working Class |

A4 |

|

Control method |

Pendant or wireless remote control |

|

Power supply |

AC 380V 50HZ(According to customer requirement) |

|

Working temperature |

-20℃~+40℃ |

|

Application area |

Mechanical processing, product assembly, equipment maintenance, warehouse, etc. |

Product Features and Applications:

1.Simple Structure: The crane consists of fewer components, ensuring quick assembly and installation without the need for complex debugging.

2.Safe and Reliable: The crane is equipped with several safety protection devices, providing a secure lifting environment.

3.Easy to Operate: It requires minimal training to control, offering user-friendly operation.

4.Energy-Efficient: With advanced control systems, the crane ensures smooth operation, saving energy during frequent start-stop cycles.

5.Versatile Design: Compatible with CD1 and MD1 electric hoists, offering solutions for both light and medium loads.

Widely used in factories, warehouses, material yards, and other indoor locations for lifting materials, offering both high efficiency and safety.

Product Details:

1.Main Beam: Made of Q235/Q355 steel for high rigidity and stability. Welded with automated machines, all welds are non-destructive tested.

2.End Beam: Cold-pressed U-shaped steel plates, welded into a box structure with a double-rim wheel set and tapered motor.

3.CD/MD Electric Hoist: Includes motor, reducer, drum, and trolley. CD is single-speed; MD is double-speed. The drum is robot-welded for strength, with a high-safety-factor wire rope.

4.Electrical System: Contact-based control system for forward/reverse operation, with short-circuit, voltage loss, and overload protections.

FAQs:

Q: What are the parts of a single girder overhead crane?

A: Key single girder overhead crane parts include the main beam, end beams, electric hoist, crane travel system, and electrical control system.

Q: Where are single girder overhead cranes typically used?

A: These cranes are ideal for indoor use in factories, warehouses, workshops, and material yards, providing efficient and safe lifting for light and medium loads.

Q: Can I get a custom design for a single girder overhead crane?

Yes, we offer custom designs to meet your specific operational needs, whether it's a low headroom single girder overhead crane or a European type single girder overhead crane.

Q: What is the typical delivery time for a single girder overhead crane?

A: Delivery generally takes 30-35 days after advance payment.

Q: How do I maintain a single girder overhead crane?

A: Regular maintenance includes checking wire ropes, lubricating moving parts, and inspecting safety systems. Follow the manufacturer’s recommended schedule.