Description

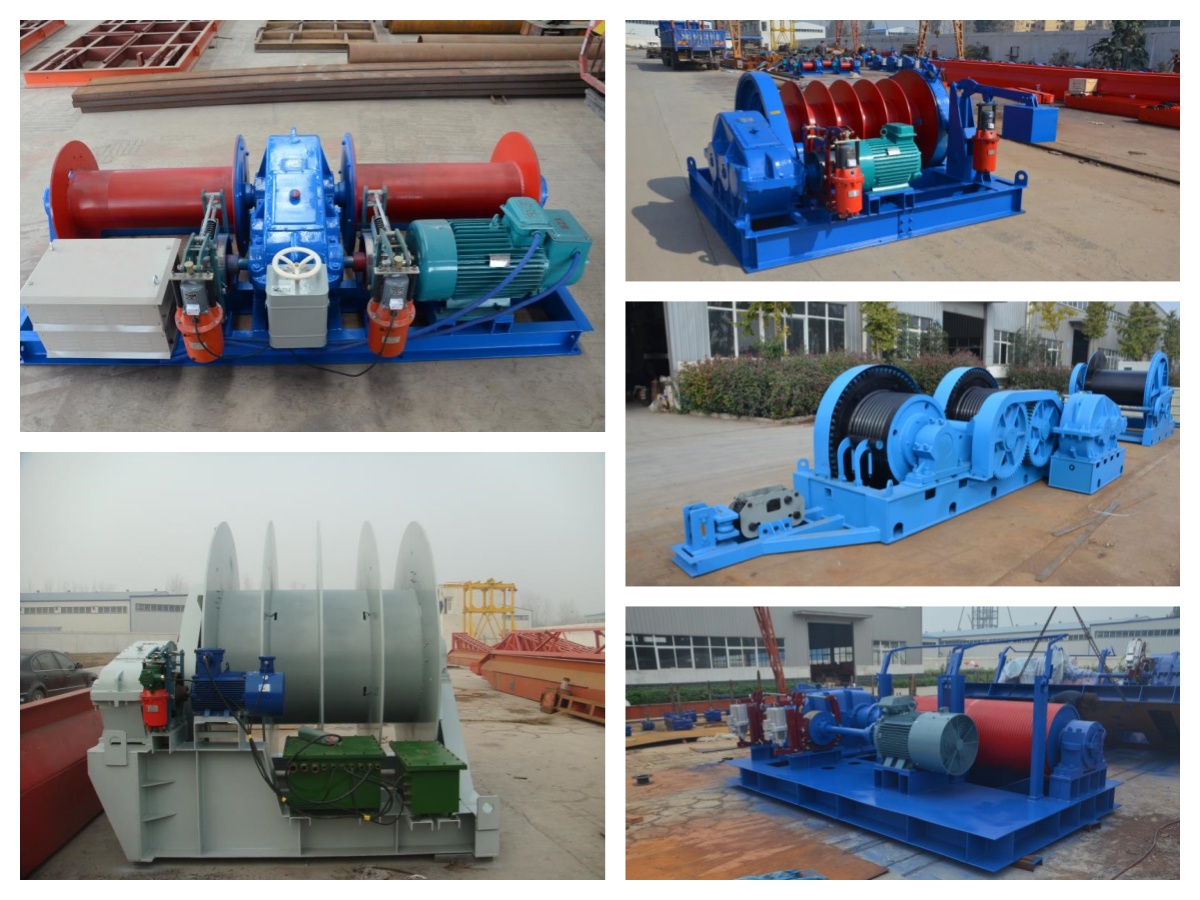

Electric Winch

Product Overview and Highlights:

An electric winch is a mechanical lifting and pulling device that uses a motor-driven drum to wind steel wire rope. It is widely used for lifting, towing, unloading, and traction operations in construction, mining, cranes, and industrial installations.

According to working speed and duty requirements, electric winches are mainly classified into JK fast speed electric winch and JM slow speed electric winch, covering both efficiency-focused and heavy-duty applications.

1.Rated load range: 10 kN – 500 kN

2.Vertical, horizontal, and inclined lifting available.

3.Stable braking system and smooth operation.

4.Large rope capacity options for long lifting or pulling distance.

5.Non-standard electric winch solutions available.

Product Parameters:

|

Type |

Rated Load (KN) |

Rated Speed (m/min) |

Rope Capacity (m) |

Wire Rope Diameter (mm) |

Motor Power (KW) |

|

JK1 |

10 |

22 |

100 |

9.3 |

4 |

|

JK1.6 |

16 |

24 |

120 |

12.5 |

5.5 |

|

JK2 |

20 |

24 |

120 |

13 |

7.5 |

|

JK3.2 |

32 |

25 |

200 |

15.5 |

15 |

|

JK5 |

50 |

30 |

200 |

21.5 |

30 |

|

JK8 |

80 |

25 |

250 |

26 |

45 |

|

JK10 |

100 |

30 |

300 |

30 |

55 |

|

JM1 |

10 |

15 |

100 |

9.3 |

3 |

|

JM1.6 |

16 |

16 |

150 |

12.5 |

5.5 |

|

JM2 |

20 |

16 |

150 |

13 |

7.5 |

|

JM3.2A |

32 |

9.5 |

195 |

15.5 |

7.5 |

|

JM3.2C |

32 |

12 |

200 |

15.5 |

7.5 |

|

JM5A |

50 |

9.5 |

250 |

21.5 |

11 |

|

JM5B |

50 |

9.5 |

250 |

21.5 |

11 |

|

JM5C |

50 |

15 |

250 |

21.5 |

15 |

|

JM5D |

50 |

20 |

250 |

21.5 |

22 |

|

JM6 |

60 |

9.5 |

270 |

24 |

15 |

|

JM8 |

80 |

8 |

250 |

26 |

15 |

|

JM8B |

80 |

9.5 |

250 |

26 |

15 |

|

JM10 |

100 |

8 |

250 |

30 |

22 |

|

JM10B |

100 |

9.5 |

250 |

30 |

22 |

|

JM12.5 |

125 |

8 |

300 |

32 |

30 |

|

JM16 |

160 |

10 |

500 |

37 |

37 |

|

JM20 |

200 |

10 |

600 |

42 |

45 |

|

JM25 |

250 |

9 |

800 |

48 |

55 |

|

JM32 |

320 |

9 |

700 |

50 |

75 |

|

JM50 |

500 |

9 |

700 |

60 |

90 |

Product Features and Applications:

1.Stable and reliable performance for lifting, pulling, and towing operations.

2.High-strength wire rope drum ensures smooth winding and long service life.

3.Powerful motor with efficient energy use and consistent output.

4.Responsive braking system provides safe and secure load holding.

5.Compact structure for easy installation and low maintenance.

6.Suitable for vertical, horizontal, and inclined working conditions.

Electric winches are commonly used in construction sites, mining areas, factories, docks, shipyards, slipways, dry docks, and crane systems. They are suitable for steel structure installation, equipment erection, material lifting, towing, and unloading operations.

Product Details:

1.Motor: High-quality lifting motor, optional protection levels.

2.Reducer: Precision gear reducer with low noise and high transmission efficiency.

3.Brake: Hydraulic brake or dual brake system for higher duty classes.

4.Drum: Seamless steel pipe or cast drum with advanced welding technology.

5.Hook: Forged steel hook with high safety factor.

FAQs:

Q: What is the difference between JK and JM electric winch?

A: JK electric winches focus on fast lifting speed, while JM electric winches are designed for slow speed, heavy-duty, and stable operation.

Q: Can the electric winch be used for horizontal pulling?

A: Yes. An electric winch can be used for vertical lifting, horizontal towing, or inclined traction.

Q: Is customization available for electric winches?

A: Yes. Load capacity, rope length, motor power, voltage, and braking system can be customized.

Q: What industries typically use electric winches?

A: Construction, mining, cranes, shipyards, factories, and industrial installation projects.