Description

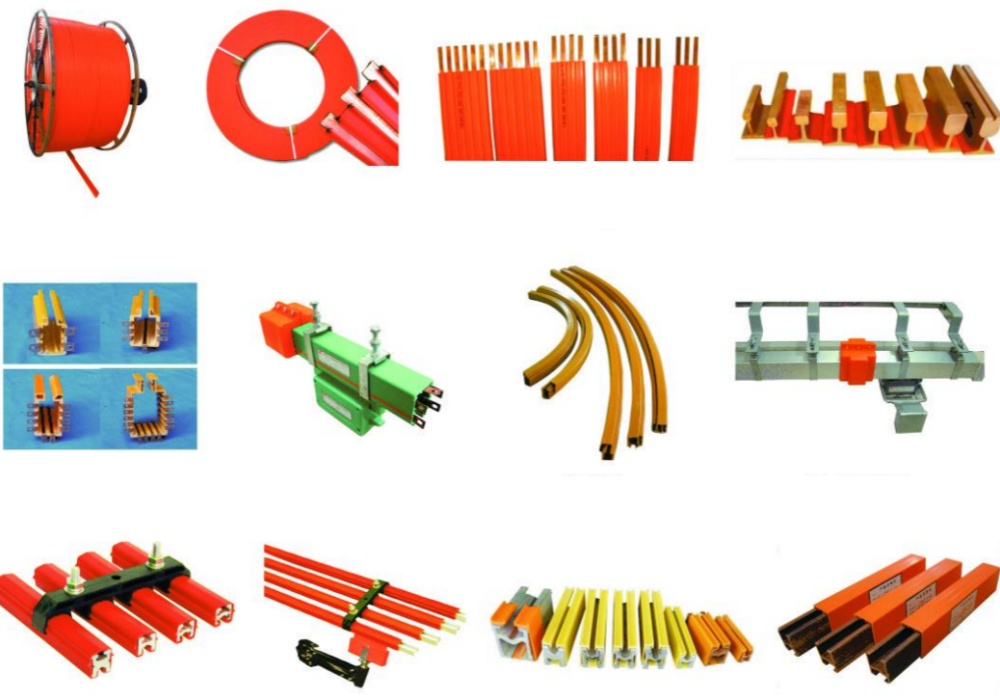

Safety Busbar

Product Overview and Highlights:

Safety busbars are crucial for providing reliable power distribution in overhead cranes, electric hoists, and other mobile electrical equipment. These systems ensure smooth and uninterrupted power supply while enhancing operational safety. The safety busbar systems are divided into three main types: Seamless Conductor Rails, Enclosed Conductor Rails, and Single-pole Insulated Conductor Rails. Each type is designed for different operational requirements, making them versatile for various industrial applications, including cranes, automated systems, and port terminal equipment.

1.Continuous Power Transmission: Ensures uninterrupted power flow with minimal voltage drop.

2.Excellent Conductivity: Made of oxygen-free copper for superior conductivity and durability.

3.Flexible Design: Customizable based on conductor type (aluminum or copper) and operational requirements.

4.Durable and Safe: Resistant to wear, corrosion, and harsh conditions, providing long-lasting and safe operation.

5.Easy Installation and Maintenance: Modular design allows for easy setup and ongoing maintenance.

Product Parameters:

|

Parameter |

Seamless Conductor Rails |

Enclosed Conductor Rails |

Single-pole Insulated Conductor Rails |

|

Conductor Material |

Oxygen-free Copper |

Copper Conductors |

Aluminum / Copper |

|

Rated Current |

16–120A |

35–160A |

200A–5000A |

|

Max. Voltage |

660V |

660V |

690V |

|

Resistance |

0.20–0.34 Ω/km |

0.02–0.34 Ω/km |

0.116–0.203 Ω/km |

|

Impedance |

1.16–1.86 Ω/km |

0.05–0.1 Ω/km |

0.067–0.39 Ω/km |

|

Surface Resistivity |

10¹³ Ω·cm |

10¹³ Ω·cm |

10¹³ Ω·cm |

|

Max. Current |

50A–120A |

50A–240A |

500A–5000A |

|

Max. Travel Speed |

≤600m/min |

≤600m/min |

≤600m/min |

|

Temperature Range |

-20℃ to +70℃ |

-20℃ to +70℃ |

-40℃ to +115℃ |

|

Flame Retardancy |

Class B1 (Flame-retardant) |

Class B1 (Self-extinguishing) |

Class B1 (Self-extinguishing) |

|

Max. Support Spacing (m) |

1.5–2.0m |

1.5–2.0m |

1.5–2.0m |

|

Housing Material |

PVC / Impact-resistant Material |

PVC / High-strength Casing |

Aluminum Alloy / Insulated Plastic |

Product Features and Applications:

1.Seamless Power Supply: The continuous conductor system ensures no interruptions in power supply, reducing voltage drops and enhancing operational reliability. Ideal for cranes, hoists, and other mobile equipment.

2.High Durability: Built with high-quality copper and PVC materials, the system resists wear, corrosion, and environmental factors, extending the service life of both the busbar and the equipment.

3.Flexible Installation: The modular design allows for easy installation, including straight, curved, and multi-pole configurations. Can be mounted horizontally or vertically, fitting various facility layouts.

4.Energy-Efficient: The use of low-resistance conductors improves energy efficiency, reduces power loss, and ensures consistent performance even under heavy loads.

5.Wide Temperature Range: The system operates effectively in a variety of environments, from -40℃ to +115℃, making it suitable for both indoor and outdoor use.

Used in overhead cranes, electric hoists, gantry cranes, port machinery, automated production lines, and elevators. Ideal for workshops, factories, garages, stations, and port terminals, offering reliable power for mobile electrical devices and lifting equipment.

Product Details:

1.Busbar Body: Constructed from high-purity copper (or aluminum alloy) with extrusion/machining process, ensuring low electrical resistance and high current-carrying capacity.

2.Insulation Layer: High-temperature-resistant flame-retardant PVC/epoxy coating (or insulated sheath) for electrical isolation and protection against short circuits.

3.Connection Structure: Standard bolted/clamped terminals (with anti-loosening design) to ensure stable electrical contact and prevent overheating.

4.Protection Components: Equipped with insulated end caps and anti-corrosion plating, avoiding electric leakage and extending service life in harsh environments.

FAQs:

Q: What is the difference between seamless conductor rails and single-pole insulated conductor rails?

Seamless conductor rails are designed for high-current applications with minimal voltage drop and no joints, while single-pole insulated conductor rails are fully insulated and offer safer operation for a variety of environments.

Q: Can these busbars be used outdoors?

Single-pole insulated conductor rails are designed for both indoor and outdoor use, while seamless and enclosed conductor rails are generally suited for indoor applications, with specific models available for extreme environmental conditions.

Q: Are these busbars maintenance-free?

While the enclosed conductor rails are nearly maintenance-free, seamless and single-pole insulated rails may require occasional checks to ensure optimal performance, especially in harsh environments.

Q: What are the installation requirements for these busbars?

Installation requires mounting the conductor rails on a stable surface. Seamless conductor rails are ideal for high-speed cranes, while enclosed rails are suited for tight spaces or environments requiring protection. Single-pole insulated rails offer flexible installation in both straight and curved systems.