Description

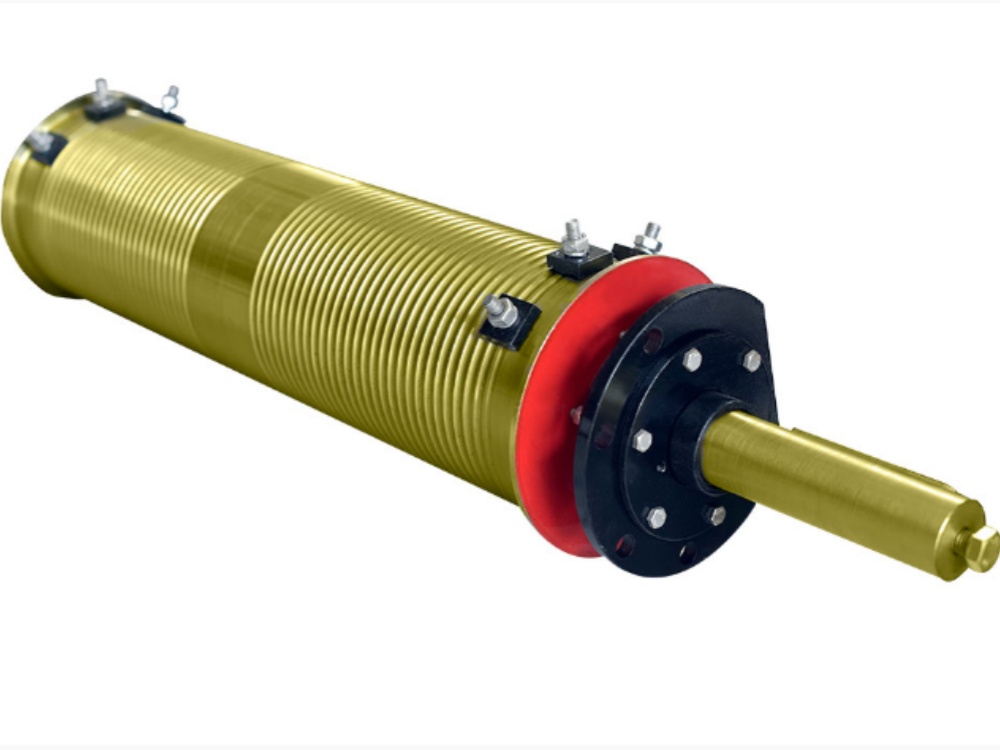

Crane Drum

Product Overview and Highlights:

The crane drum, also known as a wire rope drum or rope reel, is a critical component of crane hoisting systems. It is responsible for winding, storing, and guiding the wire rope during lifting operations, ensuring smooth motion, load stability, and operational safety. Crane drums are widely used in electric winches, hoists, and trolley mechanisms of overhead cranes, gantry cranes, and winch systems, where durability and precision directly affect service life and safety.

1.Precision-machined rope grooves for smooth and stable winding.

2.High-strength materials suitable for light to heavy-duty lifting.

3.Optimized flange design prevents rope jumping and misalignment.

4.Heat-treated grooves extend drum and wire rope service life.

5.Fully customizable dimensions, materials, and structures.

Product Parameters:

|

Parameter Category |

Typical Range |

|

Drum Diameter (mm) |

φ300 ~ φ1000 |

|

Drum Length (mm) |

800 ~ 5000 (customizable) |

|

Wire Rope Diameter (mm) |

11.5 ~ 28 |

|

Rope Groove Pitch (mm) |

Standard Groove: d + 2~4 / Deep Groove: d + 8~9 (d = rope diameter) |

|

Rope Groove Bottom Radius |

0.53 ~ 0.6 × d |

|

Drum Material |

Q235B, Q345B, Q355B (carbon structural steel); ZG25, ZG35 (cast steel) |

|

Surface Hardness (HRC) |

45 ~ 55 (after heat treatment) |

|

Supporting Structure |

Drive shaft / hollow shaft / coupling connection, etc. |

Product Features and Applications:

1.Compact Structure: Space-saving design with optimized headroom for efficient installation.

2.High Energy Efficiency: Reduced power consumption while maintaining stable lifting performance.

3.Durable Construction: High-quality materials ensure long service life and wear resistance.

4.Advanced Safety Protection: Integrated overload, phase protection, and precise limit control.

5.Smooth & Precise Operation: Variable speed control enables accurate positioning and stable movement.

6.Easy Maintenance: Modular design allows quick inspection, servicing, and reduced downtime.

Crane drums are widely used in overhead cranes, gantry cranes, port machinery, ship winches, electric hoists, beam lifting systems, mining equipment, and industrial winches. They are suitable for vertical, horizontal, and inclined lifting in construction, manufacturing, logistics, ports, and heavy industry.

Product Details:

1.Drum Body: Made from cast steel or welded steel plates for high load capacity.

2.Rope Grooves: Spiral or smooth grooves machined for precise rope guidance.

3.Flanges: Anti-rope-off flanges ensure safe winding under full load.

4.Shaft & Bearings: Designed for stable rotation and long-term operation.

5.Manufacturing Quality: Ultrasonic testing and dimensional inspection applied.

FAQs:

Q: What materials are available for crane drums?

A: Common materials include cast iron, cast steel, and welded carbon steel plates, selected based on load and working conditions.

Q: Can the crane drum be customized?

A: Yes. Drum diameter, length, groove type, shaft structure, and material can all be customized.

Q: Why is rope groove hardening important?

A: Hardened grooves reduce wear on both the drum and wire rope, extending service life and improving safety.

Q: Where are crane drums typically used?

A: They are used in cranes, winches, hoists, port equipment, shipyards, mining systems, and heavy-duty lifting machinery.